The power of 3D scanning in industry: How we can help

In today’s fast-paced industrial world, staying competitive requires precision, efficiency, and adaptability. One of the most powerful tools enabling this transformation is 3D scanning—a technology that captures the geometry of physical objects with unmatched accuracy. From manufacturing to quality control, 3D scanning has become a cornerstone for industries aiming to enhance productivity and minimize costs.

At Immertec Engineering, we specialize in providing professional 3D scanning services, including deviation reports and reverse engineering solutions, tailored to meet industrial needs. Based in Romania, we proudly serve businesses across Eastern Europe, bringing cutting-edge technology and expertise to the region.

1. Unparalleled Precision and Speed

Traditional measurement methods often fall short in capturing complex geometries. With 3D scanning, intricate details are recorded with precise accuracy within minutes. This is invaluable in industries such as aerospace, automotive, and tooling, where precision is critical.

At Immertec Engineering, we use state-of-the-art 3D scanners to ensure accurate results, whether you're validating a newly manufactured part or analyzing wear and tear on an existing component.

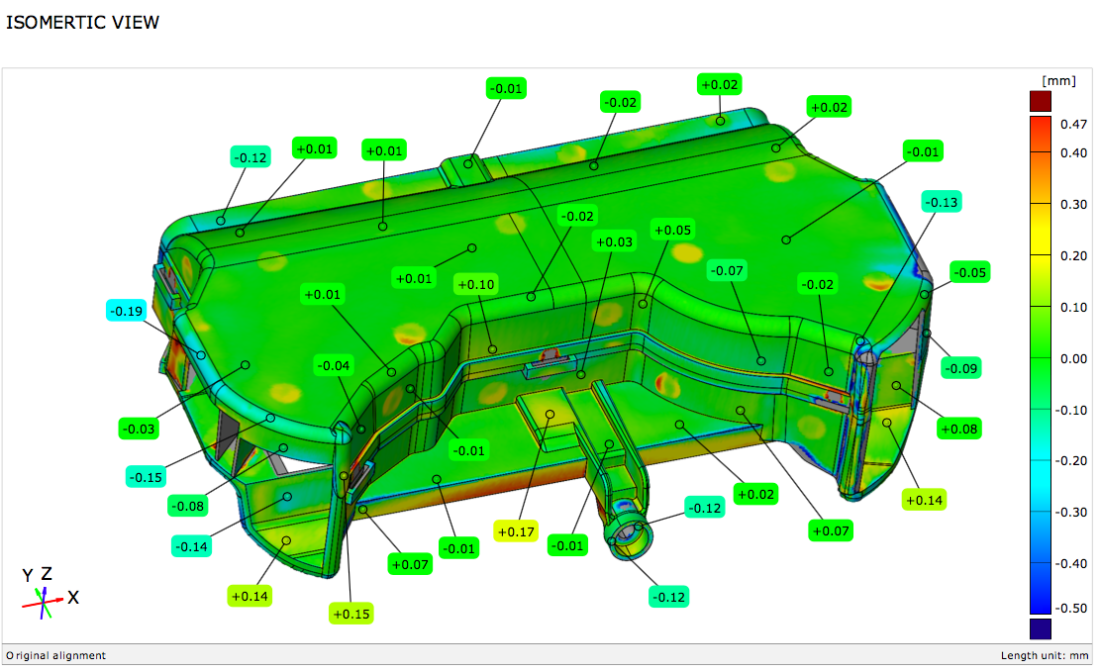

2. Enhanced Quality Control with Deviation Reports

Quality assurance is vital to maintain brand reputation and minimize production defects. 3D scanning simplifies this process by comparing scanned objects with their CAD models. The result is a deviation report that highlights discrepancies, enabling manufacturers to identify and address problems quickly.

Our team at Immertec Engineering offers comprehensive deviation reporting, providing clear insights into product conformity and helping you maintain the highest quality standards.

3. Streamlined Reverse Engineering

When original CAD files are unavailable, reverse engineering becomes essential. 3D scanning captures the complete geometry of an object, creating a digital model that can be refined or replicated. This is especially useful for legacy parts, custom modifications, or prototyping.

Immertec Engineering excels in reverse engineering, turning your physical assets into precise digital designs for further development or reproduction.

4. Cost and Time Efficiency

By reducing the time needed for manual measurements and ensuring precise results, 3D scanning significantly cuts down costs associated with errors, rework, or material waste. Additionally, it accelerates the product development cycle, helping you bring products to market faster.

5. Versatility Across Applications

3D scanning has broad applications, including:

- Tool and die inspection: Ensure molds and tools meet specifications.

- Product redesign: Quickly iterate designs for better performance.

- Maintenance and repair: Identify wear patterns and create accurate replacement parts.

- Archiving and documentation: Digitally preserve parts for future use.

- Whatever your industry, Immertec Engineering is equipped to handle your unique challenges with expert 3D scanning services.

Immertec Engineering: Your Partner in Eastern Europe

3D scanning is not just a tool—it’s a gateway to efficiency, precision, and innovation. At Immertec Engineering, we pride ourselves on offering reliable, professional services to businesses across Romania and Eastern Europe. Whether you need a detailed deviation report or comprehensive reverse engineering, we’re here to help.

Visit our website to learn more about our services and discover how we can support your business with cutting-edge 3D scanning solutions.

Transform the way you work—partner with Immertec Engineering today!